The technology of reinforced concrete, from its first steps to the present day, has highlighted numerous fragility, caused by inaccurate or superficial planning and/or supervision of works, by compositional errors in the mix design, by incorrect mixing, by errors during the casting phase and implementation of the incorrect assessment of corrosive and environmental phenomena, the absence of proper maintenance, showing more and more clearly its weakness towards external environmental conditions. For this reason, its continuous and progressive deterioration obliges to plan repair and structural restoration interventions.

Before proceeding with the necessary recovery activities of deteriorated concrete, it will be necessary to have a thorough knowledge of the causes that have led to degradation over time, by means of a scrupulous investigation which must not, however, be limited to external observation only, but must analyze in depth the characteristics of the reinforced concrete mix and the environmental conditions that may have compromised its integrity. Reckless recovery measures or only limited to filling the missing material, could even contribute to worsening the situation, increasing the damage.

The careful degradation analysis must be performed by evaluating many parameters: depth of carbonation, general conditions of the concrete cover, any cracks present (superficial or deep that they are), chemical or physical aggressions suffered by the building over time, etc.

Once the diagnostic operations have been completed and the damage has been correctly assessed, it will be possible to proceed with the restoration and structural restoration to restore the original aesthetic and functional value to the product, which must include more or less complex maintenance, restoration or reinforcement systems depending on the extent of the deterioration. A wide range of systems for restoring and reinforcing deteriorated concrete is widely described in the section “TYPES OF INTERVENTION“.

Main causes of the deterioration of reinforced concrete

They are caused by design defects, the quality of the concrete used and to its installation.

PROJECT NON-CONFORMITIES

- Wrong prescription of concrete according to the exposure environment

- Inadequate sizing of the reinforcements with induced tension states

- Inadequate on-site control of the parameters established in the planning stage (defaults in the checks by the Works Management)

QUALITY OF THE CONCRETE USED

- Wrong water/cement ratio (w / c)

- Insufficient cement dosage

- Non-compliant particle size distribution

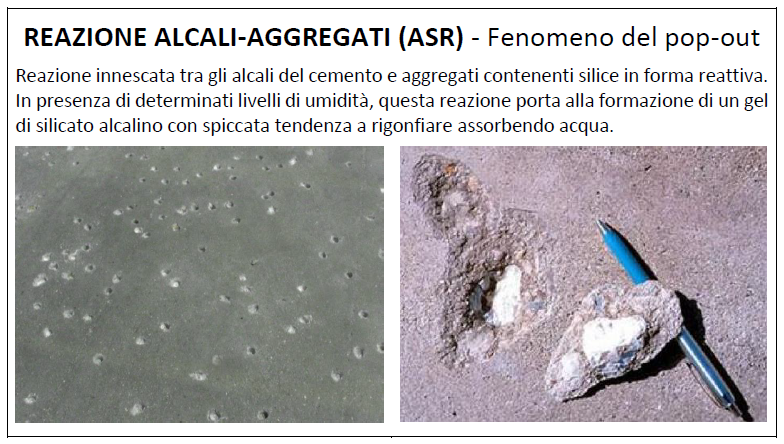

- Poor, impure aggregates or presence of alkali-reactive petrographies

- Wrong dosage of additives and/or additions

MIXING, TRANSPORT AND INSTALLATION OF CONCRETE

- Errors in mixing in the concrete batching plant

- Incorrectness during transport

- Errors in implementation (positioning of reinforcement, formwork, positioning of spacers and hermetic devices, etc.)

- Inadequate wet curing or lack of protection from thermal shock

They are mainly due to: thermal excursions, freeze/thaw cycles, abrasion-erosion, incorrectly calculated mechanical stresses.

THERMAL EXCURSIONS

The thermal expansion coefficient of concrete is = 0.000012 (° C-1). This means that the 1 °C rise of the concrete causes a linear variation of 0.000012 m/m. It may seem like a low value number, but when calculated on the delta of the thermal oscillations (between the peaks of the summer season and those of the winter season), multiplied by the length of the structure, linear excursion values come out which, if not correctly calculated and neutralized by suitable movement joints, they can lead the concrete to damage in several points. We also briefly recall the behavior of concrete at high temperatures, both for some particular operating conditions (for example structures in a steel industry) and in cases of fire: when the concrete begins to heat up, there is a first evaporation of the free water contained in the porosity of the concrete which, if it does not find sufficient escape routes, can trigger internal overpressures that can break up the matrix. Subsequently, once reached 350 °C, a decomposition of the calcium oxide present in the concrete matrix takes place and, exceeding 500 °C, there is a decomposition of the hydrated phase of the calcium silicates. These transformations lead to an increase in the porosity of the concrete and a consequent reduction in the mechanical strength of the cementitious conglomerate.

FREEZE/THAW CYCLES

The expansion of water volume in the phase transformation (equal to approximately + 9.1%) subjects the concrete to considerable stresses, also causing disintegration. How to defend yourself: one of the possible means to adopt, in addition of course to improving the impermeability through the addition of specific additives, is represented by the inclusion of air, in the form of uniformly diffused bubbles (they create expansion chambers for the water that freezes).

MECHANICAL STRESSES

Stress of the structure different from those foreseen by the project. For example:

- Unexpected accidental loads.

- Structures not suitable for the seismic response.

ABRASION, EROSION AND CAVITATION

The term abrasion defines both the stress and the degradation of a surface subjected to friction. Erosion can be considered a form of abrasion of a surface. Typical erosion phenomena are damage caused by contact and rubbing between the surfaces of a concrete structure and solid particles transported by a torrent in flood (gravels, pebbles and sands). Cavitation is a phenomenon that occurs in fluids with non-linear flows and speeds higher than 12 m/s, typical of machinery such as propellers, pumps, turbines; consists in the formation of vapor bubbles within the fluid which then implode generating heat and shock waves. The collapse of the bubbles causes extremely intense pressure waves and microjets so that, if the implosion occurs near a concrete wall it can cause damage and erosive cavities.

They are mainly due to the disintegrating action of salts and chlorides, to chemical aggressions in a general sense, to carbonation and contact with low hardness water, to stray currents.

SALTS AND CHLORIDES

This phenomenon is especially present in the marine environment or due to the massive use of de-icing salt on roads and motorways in the winter.

The salts cause the formation of concentrated solutions of sodium and calcium chloride and chloride ions. These activate heavy corrosive processes towards the steel reinforcement.

CHEMICAL AGGRESSIONS: ACID RAIN AND SULFATE ATTACK

Acid rain is the result of the fallout from the atmosphere on the soil of acid particles derived from combustion in industrial processes and in the production of electricity which, in the form of smoke and smog, have risen into the atmosphere. They have a pH below neutrality: they damage reinforced concrete by both neutralizing calcium hydroxide and dissolving calcium carbonate.

Natural and industrial acid-type chemical agents, or oils, fats and sulphates, on the other hand, can lead to the formation of cracks, to expansive reactions with consequent spalling, or in extreme cases even to the disintegration of the cement matrix (in particular the sulphate ion causes swelling, localized tension and severe damage to the concrete).

CARBONATION

Initially in the concrete, following the hydration of the cement and the development of Ca(OH)2 hydrolysis lime, conditions of strong basicity are established, particularly favorable for the good preservation of the metal reinforcements. In this situation, called passivation, an impermeable ferric oxide film is formed on the iron and strongly adheres to the steel, which prevents oxygen and humidity from coming into contact with the reinforcing bars, preventing the formation of rust. The carbon dioxide (CO2) present in the air, penetrating the concrete through its porosity, progressively decreases the basicity of the conglomerate, due to the transformation of the Ca(OH)2 hydrolysis lime into calcium carbonate CaCO3. At a pH lower than 11 the concrete, in technical terms, depassives, undergoing corrosion and rust formation, as the oxide film becomes porous and is no longer able to block the access of oxygen and moisture towards the metal substrate. Following the transformation of iron into rust, which is 6-7 times more voluminous than metal, the concrete cover is first cracked and then ejected («spalling»

LOW HARDNESS “LEAVING” WATERS

They are represented by some examples of waters with extremely low salt content:

- Natural waters of glaciers and snowfields

- Distilled and/or industrial recovery waters

Their “poverty” in salts means that these waters, flowing against the concrete walls represented by channels, pipes, etc …, tend to acquire salts from the concrete itself, through the dissolution of calcium hydroxide or calcium hydroxide (Ca(OH)2).

VAGANT CURRENTS

Frequent in urban areas, especially in the presence of railway lines, subways and tramways, etc … These are currents dispersed by electrical circuits that enter the metal elements, encouraging their corrosion.